- 华泰智能设备集团应邀参加中国粮油学会第十二届学术年会

- 华泰智能装备集团出席第三届稻米油产业技术创新战略联盟会议 共促产业高质量发展

- 深化合作,寻求双赢!粮油多多与华泰智能设备谈国际粮油机械市场发展!

- 华泰智能设备集团与河南工业大学签订合同 油加工技术创新的新篇章

- 华泰智能设备闪耀广州粮油机械展,低温提取技术获金奖

- 华泰智能设备集团100TPD棕榈油提升设备启动巴基斯坦 推动中巴油脂产业合作迈上新台阶

- 华泰智能设备350T/D葵花籽榨油,200T/D浸出设备送往哈萨克斯坦

- 校企深度融合 智创粮油未来——武汉轻工大学与华泰智能装备集团联合举办了大豆深加工和甘油二酯食用油制备技术创新研讨会

- 华泰智能设备100 T/交付D棕榈油精炼成套设备,开启刚果金棕榈油行业的新篇章

- 15T/D茉莉花和玫瑰提取成套设备由华泰智能设备集团投产 赋能西双版纳"芳香经济"高质量发展

联系人:闫经理

手机/微信:158-9680-3999

地址:河南省滑县新区湘江路与富民路交汇处

大豆预处理车间工艺以及我公司大豆预处理工艺的特点

大豆预处理车间工艺描述:

大豆 ------> 计量------> 磁选------> 除铁------> 清理------> 去石------> 齿辊破碎

软化------> 轧胚------> 膨化------> 冷却干燥------> 浸出

我公司大豆预处理工艺特点:

1.全部连续化、机械化操作;并带有电器联锁控制系统;

2.设备布置采用塔楼式结构,物料尽量依靠重力流动,降低动力消耗;

3.膨化工段设计时考虑生产不同比例膨化料和生坯浸出的情况,根据产品的需求随时调整;

4.生产胚片豆粕时,使用滚筒软化锅更加适合压胚的工艺要求;

5.考虑到现代工业的环保要求,在本车间亦配有较强能力的除尘系统,以满足生产和环保的要求;

6.在输送过程中尽可能多地选用刮板输送机,有效减少了输送过程料坯的破碎,有利于浸出过程中溶剂对料层的渗透,提浸出效率;

7.我公司还在轧胚工序的后面加上大豆膨化工序,对豆胚进行膨化,以进步破坏油料细胞的结构,大大提升产量,得到受饲料厂家欢迎的膨化粕。

工序描述:

计量工序:采用专用设备,计量称生产稳定,用于调节流量和计量生产总量,且能达到累计计量、瞬时计量和成本核算的目的,计量准确,精度。

清理工序:采用磁选器去除铁杂;振动清理筛去除大杂、秸秆等;比重去石机去除石子和砖块等重杂;除尘系统采用单联刹克龙以及离心风机进行有效的除尘,以保证车间卫生和清理轻杂。

软化工序:采用YRHW系列卧式软化锅,通过进料绞龙进入软化转筒内,随着转筒的转动,物料得到不断的翻动,由于转筒内装有加热列管,列管内通有蒸汽,因此物料在随着转筒不断翻动的同时,将大豆加热到50-70℃,使其充分软化,提大豆原料的塑性,使轧胚机轧出的胚薄而不碎,从而提浸出效果。转筒带有进料端、出料端低的倾角,根据物料的软化情况,通过调速装置调节转筒的转速,可以控制物料在转筒内的软化时间,使物料的软化效果达到佳状态。

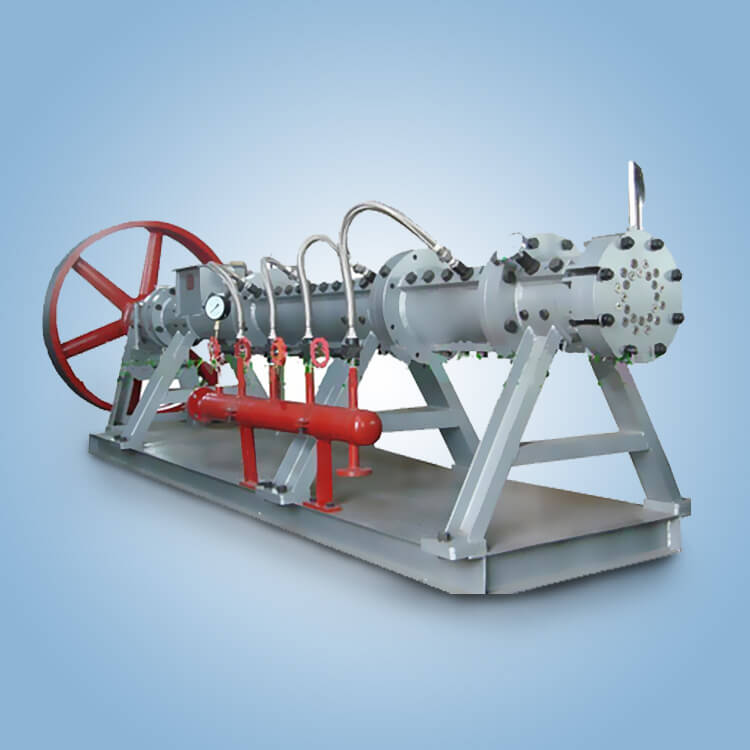

轧胚工序:采用液压紧辊轧胚机,较好的破坏油料细胞组织,以保证轧坯片薄而均匀,有韧性,粉末度小。

Soybean pretreatment process description:

Soybean→metering→magnetic separation→deironing→cleaning→stone removing →gear roller crushing→softening→flaking→extrusion→cooling&drying→extraction

Characteristics of our soybean pretreatment process:

1. Full continuous and mechanized operation, and with electrical interlocking control system.

2. The equipment layout is in tower structure, and the material flow by relying on gravity to reduce reducing power consumption.

3. In extrusion process, consider producing extrusion material in different proportions and raw germ extraction, and adjust it at any time according to product requirements.

4. When producing soybean germ meal, the roller softening pot can better meet the flaking technical requirements.

5. Take into consideration the environmental requirements in modern industry. The workshop is also equipped with the dedusting system with high performance, so as to meet the requirements of production and environmental protection.

6. Select scraper conveyor as much as possible, which can effectively reduce raw material crushing, improve solvent permeation into the material layer, and increase the extraction efficiency.

7. Our company adds soybean extrusion process after flaking process, to extrude the soybean germ, further destroy oil material cell, improve the productivity greatly and get the extruded meal that is well-received by feed manufacturers.

Process description:

Metering process: with special equipment, the stable measuring scale is used to regulate the flow and measure total production. Moreover, it can achieve accumulated measurement, transient measurement and cost accounting, with accurate measurement and high precision.

Cleaning process: use magnetic selector to remove iron impurity, vibration cleaning sieve to remove straw, and gravity stoner to remove stones, bricks and other impurities. The dedusting system uses single union cyclone and centrifugal fan to remove dust effectively, so as to to ensure workshop hygiene and clear light impurities.

Softening process: with YPHW series horizontal softening pot, material enters softening drum through feeding auger, and turns over with the rotating drum. The rotating drum is equipped with heating tube, and there is steam in the tube. When material turns over continuously with the rotating drum, soy is heated to 50-70℃ and is fully softened, which can improve soy plasticity, make germ flake thin and burly and improve extraction effect. In addition, the rotating drum has the inclination of high feed end and low discharge end. According to material softening conditions, regulate the rotating speed of drum to control the softening time of material in the rotating drum, so as to achieve the best softening effect.

Flaking process: our hydraulic compact roller flaker can better damage the oil material cell to ensure thin and uniform flake, with high toughness and small powder.